|

|

Property

With wide applicable temperature scope of - 60 ℃~+ 250 ℃ and low dynamic fractional coefficient (0.05), PTFE and rubber composite material provides excellent self-lubrication, improves wear resistance, reduce the rubbing temperature rising at main lip area of oil seals and largely promotes the max working linear velocity.

This composite material not only has excellent mechanical and chemical properties but also possesses excellent elasticity as rubber elastomer dose. So it can meet the technical requirement of oil seals.

When working in dynamic conditions, the rubber and PTFE composite material has so many cherish properties such as traceability that it is used widely. It improves the quality grade largely and expands the application of the sealing basic material. At the same time, the rubber and PTFE composite material overcomes the technical difficulty in seal industry successfully, especially when working in harsh conditions such as in high temperature, high-velocity, high pressure, etc situation.

PTFE and rubber composite material Oil seals

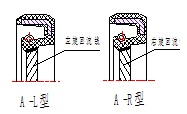

Under consideration of different operating modes, we develop and design the Type-A and Type-B PTFE and rubber composite materials oil seals.

|

( Click the picture to enlarge ) |

Type-A composite material oil seal

The PTFE sheet from 0.2mm to 0.6mm is recombined with the rubber on the main lip area of oil seals by curing method . This structure can restrain rubbing temperature rising, and improve rotational linear velocity upper limit largely( linear velocity limit: from 30m to 60m/s).

This structure meets the traceability requirement of dynamic sealing depending on elasticity of rubber and compensation function of spring, and is applicable for dynamic sealing condition within 0.1 amplitude of vibration. The working pressure ≤ 0.05Mpa.

|

( Click the picture to enlarge ) |

Type-B composite material oil seal

The Type-B oil seal is made by chemical technology of graft copolymerization. Recombining PTFE sheet from 0.4mm to 3mm to rubber of oil seals ,we can obtain the memory function of PTFE to keep the main lip close to the shaft. The PTFE and rubber composite material can restrain the rubbing temperature and increase the working rotational linear velocity upper limit (working linear velocity 30m-60m/s).

Utilization of the prestressing force of PTFE and rubber composite material can meet the tracking requirement under dynamic sealing conditions. This structure is applicable to dynamic sealing area such as high temperature, high-speed, high pressure (pressure upper limit 32 Mpa ),etc.

Application: gas separation machinery, hevery duty engineering machinery, diesel-driven generator of petrochemical industry and other fields.

|

|

Type-A-L rotary shaft lip seal has double lips and unidirectional left -handed backflow ditch. Type-A-R rotary shaft lip seal has unidirectional right-handed backflow ditch. Both seals have good stopping properties.

|

| |

|

|

| |

( Click the picture to enlarge ) |

Type-C oil seal

The Type-C oil seals are made from PTFE and special fillers. There are a spring to keep the sealing lip close to the shaft. They can work without lubricant.

Scope of application: strong acid, alkali, water etc medium. Operating mode: dynamic friction.

|

( Click the picture to enlarge ) |

Type-AB oil seal

The Type-AB oil seal is the combination of Type-A and Type-B. It can isolate the different pressure chambers.

Scope of application of medium: strong acid, alkali, water etc. |